An ERF/MRF Facility Case Study – Reducing Conveyor Stoppages with Automatic Motorised Brush Cleaning Technology

The Problem

At the ERF/MRF facility, the existing belt scrapers encountered significant issues with material buildup at the head drum end, where the scraper blade contacts the belt. This buildup required regular maintenance and cleaning, which in turn demanded substantial manpower.

When these scrapers were not maintained regularly, the excess material was carried back along the belt, leading to several operational problems:

– Belly pans filled with material.

– Blockages around rollers.

– Material pushing from the belly pan to the underside of the belt, causing premature wear and damage.

– Overloaded drive drum motors.

– Spillages on the facility floor, posing health and safety hazards.

Stoppages

The accumulation of material in belly pans, excessive drive drum load, and reduced belt speed led to frequent stoppages. These issues not only disrupted operations but also caused:

– Premature wear to the conveyor belt and return rollers.

– Health and safety hazards due to spillage on the facility floor and gangways.

– Increased cleaning requirements and manpower.

The Hoverdale Solution

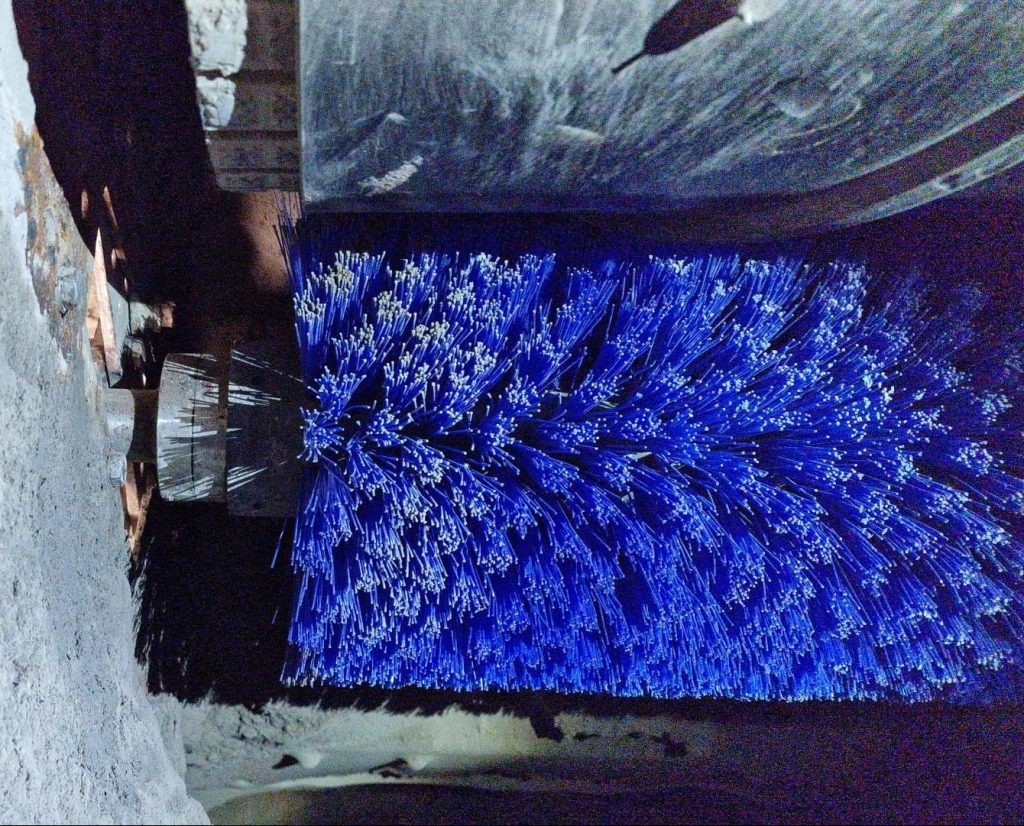

Given the varied construction of rubber conveyor belts, including cleated, chevron, and flat belts, conventional belt cleaners proved inadequate. A new approach was necessary to ensure effective belt cleaning and prevent carryback and spillage. The Hoverdale Motorised Brush emerged as the ideal solution.

This motorised brush features:

– Stainless steel construction that auto-adjusts to maintain effective cleaning contact as the brush wears.

– A range of cleaning brush diameters from 200mm to 600mm, effectively cleaning cleated belts up to 150mm in height.

– Quick-release cartridge systems for fast and easy brush changeovers.

The Results & Benefits

Implementing the Hoverdale Motorised Brush brought significant improvements:

– Elimination of carryback, preventing blockages.

– Clean return belt and rollers, free from material buildup.

– Reduced need for cleaning resources, minimising health and safety risks.

– Clean belly pans, free of material.

– Reduced downtime and increased uptime, leading to stable production.

– Reduced wear on conveyor belts and rollers, lowering ongoing costs.

– Minimal maintenance required, saving on manpower and resources.

Conclusion

In summary, the adoption of the Hoverdale Motorised Brush at the ERF/MRF facility effectively addressed the challenges posed by the existing belt scrapers. The facility experienced a significant reduction in conveyor stoppages, improved operational efficiency, and enhanced safety conditions, showcasing the effectiveness of automatic motorised brush cleaning technology.

Download our full case study:

The Hoverdale Motorised Brush Cleaner offers a reliable solution to these challenges, ensuring clean and efficient conveyor belt operations. By investing in such advanced cleaning technology and maintenance services, MRFs can optimise their processes, reduce costs, and contribute more effectively to a sustainable future.