How to track a conveyor belt: Conveyor belt tracking is only necessary when a belt ‘wanders’ from side to side, causing belt edge damage, premature belt failure, structural damage and, in extreme cases, a fire risk.

Because of the geometry and design of our belt conveyor systems, we are able to fix conveyor belt tracking belts that steer the belt toward the centre whenever the belt is moved out of position.

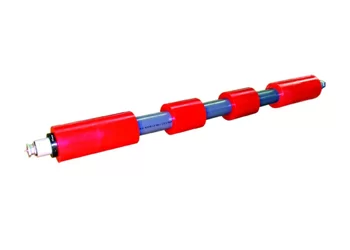

- Our belt tension trackers are renowned for their long lives.

- Our no-mo disks are a low-cost solution for a light application.

- Our trackmaster system is a heavy-duty system that will cope with difficult tracking problems.

- Our conveyor frame systems are used for the most important belts in plants (like blast furnace feed belts) and are relied upon for the most demanding conditions.

Customers with conveyor belt tracking are commonly interested in:

- Preventing belt edge damage – this usually means that clients have to replace belts sooner than they need to, causing downtime & extra costs.

- Preventing structural damage – the structure of the conveyor system can be even more expensive to replace & can be extremely difficult to get to and maintain.

- Preventing spillage – spilt material can cause structural & belt damage & can cause huge increases in clean-up costs.

Hoverdale can offer value in a number of ways to customers who have belt tracking issues:

- Extending the life of conveyor belts and preventing damage – in most cases, we can extend belt life by 2 – 3 times.

- Preventing structural damage to conveyor systems – significant maintenance issues can arise as a result of structural damage that can cause extra maintenance, lost throughput, downtime & costly additions of wear plate & patching of the systems.

- Preventing spillage – spillage is a significant problem that can absorb man-hours unnecessarily.

- Developing long-term cos-saving solutions – our willingness to come out & discuss problems with site engineers can help develop custom solutions to complex problems that can save hundreds of thousands of pounds over the life of a system.

Hoverdale will survey the belt in question and present a proposal that will ensure that the belt will track correctly onto the head pulley, track correctly into the GTU & track correctly onto the tail drum.

The first thing we will do is to check your belt alignment. If you have a wandering belt, our trackers will help. We would often fit a troughing tracker two and a half belt widths from the discharge, a flat tracker tracking the belt into a GTU and a final tracker two and a half belt widths from the tail drum so that your belt goes onto and comes off of your tail drum square.

Correct tracking is the key to structural damage. We can advise as to the correct tracking systems as well as using our expertise with cleaners, rollers, hard metals and our 45 years of consultancy to give you the best solution.

Spillage is usually a problem that can be dealt with using a combination of trackers, skirts & cleaners.

If you are getting a lot of spillage, we would live to be challenged to deliver a survey as we can guarantee you will be happy with the results.

Our Offer To You

- Reduce downtime due to unscheduled break downs

- Save on equipment cost & renewal costs

- Save man hours on maintenance

- Minimising & eliminating lost production

- Increase their bottom line by achieving savings in all of the above

Save Time & Money with Hoverdale

- Total transparency – get the best advice from the people who are directly involved in engineering and installing the solutions

- Improving housekeeping – working with you to reduce spillage and to determine the benefits in terms of reduced maintenance & clean-up costs

- Increasing plant availability – extending the periods between maintenance by installing the right solution

- We work with you to achieve a program of planned maintenance – we can custom-make products to last the length of time you need them to last to fit in with your planned maintenance programme

- Engineering solutions to high-cost maintenance problems – our engineering expertise gives us a unique ability to dramatically reduce maintenance costs with the most simple solutions

- Reducing maintenance costs – the correctly designed conveyor system will have a huge effect on maintenance costs that we can help you to identify, quantify and realise