Belt cleaner and scrapers: Hoverdale has a unique combination of experience and engineering know-how as conveyor belt equipment manufacturers UK, which we can guarantee you won’t find anywhere else.

Hoverdale manufacture 28 different types of conveyor belt cleaners and scrapers in the UK, our conveyor belt cleaning system provides the right product for each different type of job. We manufacture all of our conveyor belt cleaners and scrapers in the UK for regular conveyor belt maintenance, offering our own range of products to do the job perfectly each time. No two plants are exactly the same and variations that affect our customers include:

Belt Speed

Access to Transfer Points

Material Transported – From Heavy Clay to Powdered Glass

Acidic Materials

Alkali materials

Gels & Liquids

Moisture Content

Particle Size

To provide belt cleaner & scrapers that provide excellent results every time, Hoverdale relies on our range of 28 different systems and our 50 years of experience to give our customers the best results at the best price.

We are specialist problem solvers and our systems work where others fail. We are confident in our conveyor belt cleaners and we invite you to present us with your problems to solve.

Request a FREE SITE SURVEY:

Browse Belt Cleaners & Scrapers

Primary Belt Cleaners & Scrapers

Secondary Belt Cleaners & Scrapers

All our belt cleaners & scrapers are Made in Britain

Primary Belt Cleaners & Scrapers

Primary belt scrapers are designed to remove debris known as ‘carryback’ from the belt surface, which can otherwise be transferred to the rest of the conveyor system. This causes extra wear and tear, and potentially shortens the life of the conveyor.

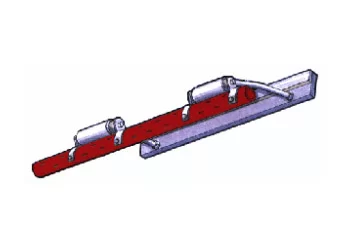

Primary belt scrapers can consist of either a single blade which passes along the width of the belt, or a series of short blades, with different blade material available to suit the individual system. They are installed at the head pulley, and can have adjustable torque or suspension systems to allow continuous contact with the belt surface at all times.

Secondary Belt Cleaners & Scrapers

The secondary cleaner is usually used in addition to a primary scraper. It is normally installed between the drive pulley and the first supporting roller to give the most effective performance, and clear any smaller waste particles which were not picked up by the primary cleaner.

There are several different types of belt cleaner and scraper available, to suit different types and sizes of machine, and the type of material transported. Secondary cleaners can be used without the primary cleaner, for example if the material is dry and fine.

Non Contact Scrape Air

Moist to sticky materials are most suited to non-contact systems, which use an air suction method to remove spillages from the conveyor surface. They can also be used with a spray bar for effective cleaning of dry and dusty materials.

Non-contact scrape-air conveyor belt cleaners cause no belt wear because they do not have any mechanical contact with the belt. They are a cost-effective and low maintenance solution for chevron belts and damaged belts, and are ideal for acidic materials.

They can be supplied with self-cleaning filters to minimise maintenance costs, and are also available with bypass regulators to control delivered air volume.

Chevron

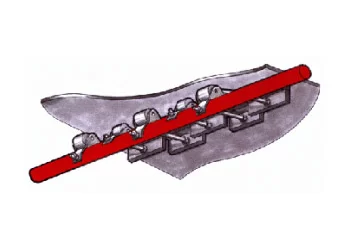

The Chevron secondary conveyor belt cleaners are specially designed for chevron, raised-rib, or cleated conveyor belt surfaces, which are difficult to clean with other methods.

If material is allowed to build up on the belt surface, it leads to carryback, which causes extra wear and tear on the rollers and drum. This increases maintenance costs. and shortens the life of the machine.

Chevron belt cleaners have rotating rubber discs which move in a sweeping action to remove debris, and can either be solid or notched to suit the conveyor belt speed and the spacing of the chevrons. They are suitable for wood processing, mineral, mining, and recycling plants.

The Hoverdale motorised brush is designed to clean a range of belt constructions including

- Chevron belts

- Cleated belts

- Flighted belts

- Vulcanised or mechanical joined

The rotation action working against the belt’s direction is designed to dislodge material stuck between the chevron patterns, cleats , and also very effective on flat belts.

Proven technology working in many industries to include

- Waste & recycling

- (IBA) Incinerator bottom Ash

- Food & Beverage (FDA Approved)

- Wood processing & Recycling

- Mining

- Aggregates

- Power generation

- (MRF) Material recovery facilities)

- (ERF) Energy from Waste

- (RDF) Refuse devised fuel

- Wastewater treatment plants

- (AD) Aerobic digestion

- Animal waste removal

- Optical Sorters

- Cement

- Gypsum

- Metal Recycling

- Port & Ship Loading

- Sea Aggregates

- Biofuel

Replacement Blades

High quality primary belt cleaner blades are important to ensure the best cleaning performance. Replacement blades are available for a wide variety of belt cleaning systems, and are effective at removing spillages and debris from the belt surface.

Ineffective belt cleaners, either because the blades need replacing or because the cleaner isn’t suitable for the system and material type, leads to damage to the conveyor system. This can mean unscheduled downtime, extra maintenance work, and increased safety risks. Therefore, it is important to replace blades when the show signs of wear.

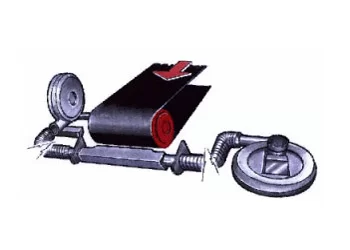

HALO System

The HALO system can identify and report information when the system has a worn blade and automatically removes blockages by disengaging from the belt, cleaning the blade, and then re-engaging the blade with the belt to the correct tension. All whilst the plant is still running.

Belt Cleaners & Scrapers: A Quick Guide

Why it is important to use the right belt cleaners

Keeping conveyor belts free from waste remnants is a widely recognised problem in processing plants. If particles are not fully removed, it can cause material build-up on the conveyor surface, which is transferred to the return rollers and tail drum, a problem known as ‘carryback.’

Conveyor belts which are not kept properly clean are prone to tracking issues and damage to the belt, which means more downtime and higher maintenance costs. This is why it’s important to install the most effective primary and secondary belt cleaners and scrapers for the type of machine, and the materials it handles.

Belt scrapers are used throughout a wide variety of industries. They are commonly found in recycling and material sorting plants, and the wood chipping, mineral processing, mining, and scrap metal sectors.

What are the different types of belt scraper?

Primary belt scrapers are the first line of defence against material build-up, and they are designed to remove residual material after the belt has unloaded. Primary scrapers are especially suited to removing coarse particles, and gels and liquids. Secondary scrapers are used to remove any remaining residue after the primary scraper has passed along the belt.

There are a number of different designs, to take into account different plant uses. For example, some belt scrapers are designed to work at lower or higher belt speeds, and with different types of belt surface, such as ridged or chevroned. Other factors which might affect the choice of scraper include the working environment and temperature.

The belt scraper can also be selected so that it is the best fit for the type of materials transported. For example, the moisture content, acidity or alkalinity levels, the consistency, such as fine powder or heavy clays, and the particle size. They are typically made of plastic, rubber, or metal, and can consist of a multi-blade system, or a single blade.

For material which is of a wet or sticky consistency, non-contact scraper air systems may be the best solution. These use an air suction method to remove materials from the belt surface. They are also suitable for removing fine, dusty or powdery materials from the belt surface, when used in conjunction with a spray bar.

Non-contact scraper air systems have the advantage of causing no damage to the belt, so they are ideal for harsh and abrasive materials, and will work effectively on damaged belts.

What other factors affect the performance of a belt scraper?

As well as selecting the right cleaner, it is important that they are installed correctly, and inspected regularly for signs of wear and tear. The abrasive nature of the scraping and cleaning process means that even good quality products will occasionally need adjusting or blades replacing to ensure that they are performing to a high standard.

A belt which is old or in a poor condition will also affect the performance of the cleaner and scrapers. The better the cleaners and conveying system are maintained, the more effective they will be, and the plant will have less downtime and increased productivity and profitability.

Many companies offer only one system and it is well known that one system will not be at its best in all situations. Hoverdale are ‘armed’ with 13 systems each with different blade options and backed by 40 years’ experience at problem solving. We are confident that we can provide the results that you expect.

The largest system we have made was for a 4m belt which has been working perfectly for 2 years.

We can offer an air knife that will remove carry back without touching the belt.

We can offer a product specifically designed to resist acid attack which we will guarantee to do the job.

Yes we can. We will offer long life systems that will run for long periods without maintenance. The longest is 8 years – could be a world record!

Our Offer To You

- Reduce downtime due to unscheduled break downs

- Save on equipment cost & renewal costs

- Save man hours on maintenance

- Minimising & eliminating lost production

- Increase their bottom line by achieving savings in all of the above

Save Time & Money with Hoverdale

- Total transparency – get the best advice from the people who are directly involved in engineering and installing the solutions

- Improving housekeeping – working with you to reduce spillage and to determine the benefits in terms of reduced maintenance & clean-up costs

- Increasing plant availability – extending the periods between maintenance by installing the right solution

- We work with you to achieve a program of planned maintenance – we can custom-make products to last the length of time you need them to last to fit in with your planned maintenance programme

- Engineering solutions to high-cost maintenance problems – our engineering expertise gives us a unique ability to dramatically reduce maintenance costs with the most simple solutions

- Reducing maintenance costs – the correctly designed conveyor system will have a huge effect on maintenance costs that we can help you to identify, quantify and realise