Eliminate Your Conveyor Carry-back Problems

Our newly enhanced Skalper® series of conveyor belt pre-cleaners have been installed and have solved carry-back problems all over the world. The simple and highly effective Skalper® belt cleaner removes carry-back from the conveyor system.

Skalper® Belt Cleaner Features & Benefits

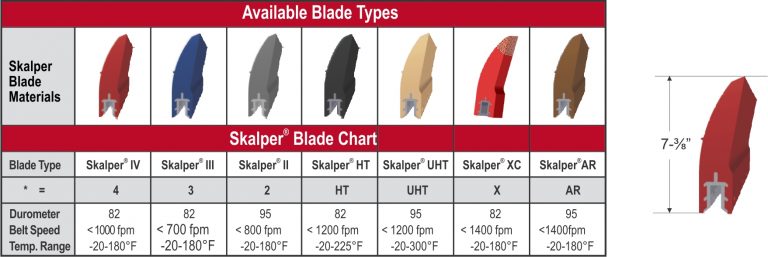

- Excellent Performance – of our patented Skalper® Blade design maintains an effective cleaning edge throughout the life of the blade with its unique horizontal sipes/wear-grooves across the entire width of the blade cleaning edge and by the use of the arc-shaped back side of the blade to ensure a sharp cleaning edge.

- E-Z Torque® Tensioner – (lifetime warranty) patented – made of all 304 stainless steel mounting plates, collars and springs allows the blades to self adjust throughout the entire life of the blade and is the most robust and accurate belt cleaner tensioner in the industry.

- Blade-Wear Indicator – allows to monitor blade wear easily without having to shut the system down for inspection.

- Torque Spring – provides a greater degree of tensioning per inch of blade, verses compression springs which require more tensioning adjustment for the life of the blade.

- Rubber Corrugated Dust Covers and UHMW Bushings – ensures no build-up in the spring tensioning area and provides smooth non-binding tensioning.

- Quick-Change Blade – stainless steel pin blade change-out system uses no-tools.

- Optional – Ceramic (XC) blade available for high speed, high tonnage conveyor systems.

- Easily Maintained – and tensioned from one side of the conveyor.

- MSHA Accepted – #MSHA IC – 174/1

Skalper® Belt Cleaner Video

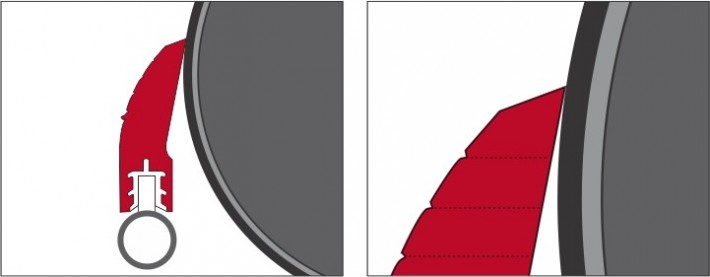

Blade Angle

A flat pulley surface side of the blade ensures a sharp point contact and material clearance.

- More Aggressive

- Self-Sharpening

- Less Abrasion Between Blade and Belt

- Less Chance of Blade Feathering

Product Specifications

- Maximum Belt Speed – 1000fpm (5.0 m/sec)

- Pulley Diameter – 12″ – 36″ (300 – 900mm)

- Applications – Coal Fired Power Plants, Hard Rock Mining, Steel Mills, Iron Ore, Aggregate and Mineral (Phosphate, Potash, Salt) Mining

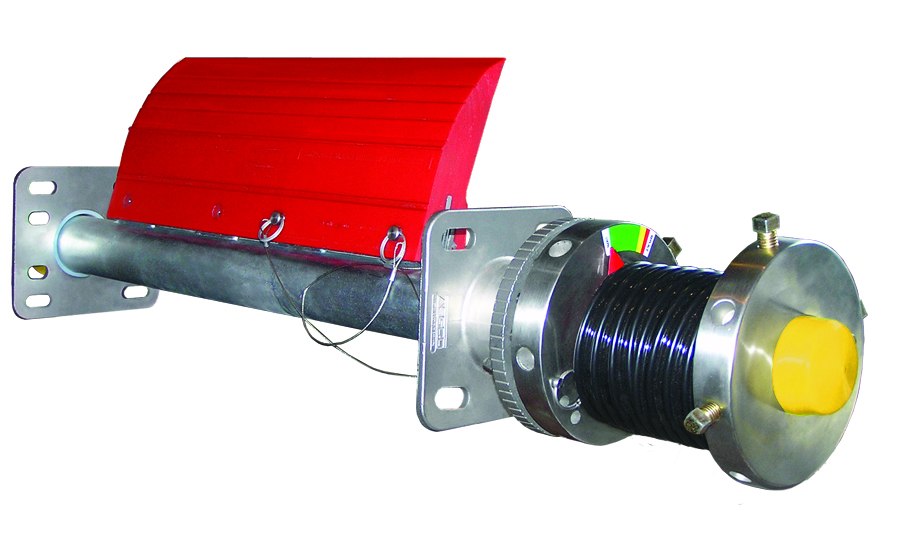

Skalper® with E-Z Torque® Tensioner

- Simple and Accurate

- Superior Elasticity

- Excellent for worn belts

- Stainless steel pin with lanyard for easy change-out

- Single hand tensioner

- Torque wrench adaptor supplied to get accurate torque tension.

- 100% Lifetime warranty

- US Patent Number 5,992614