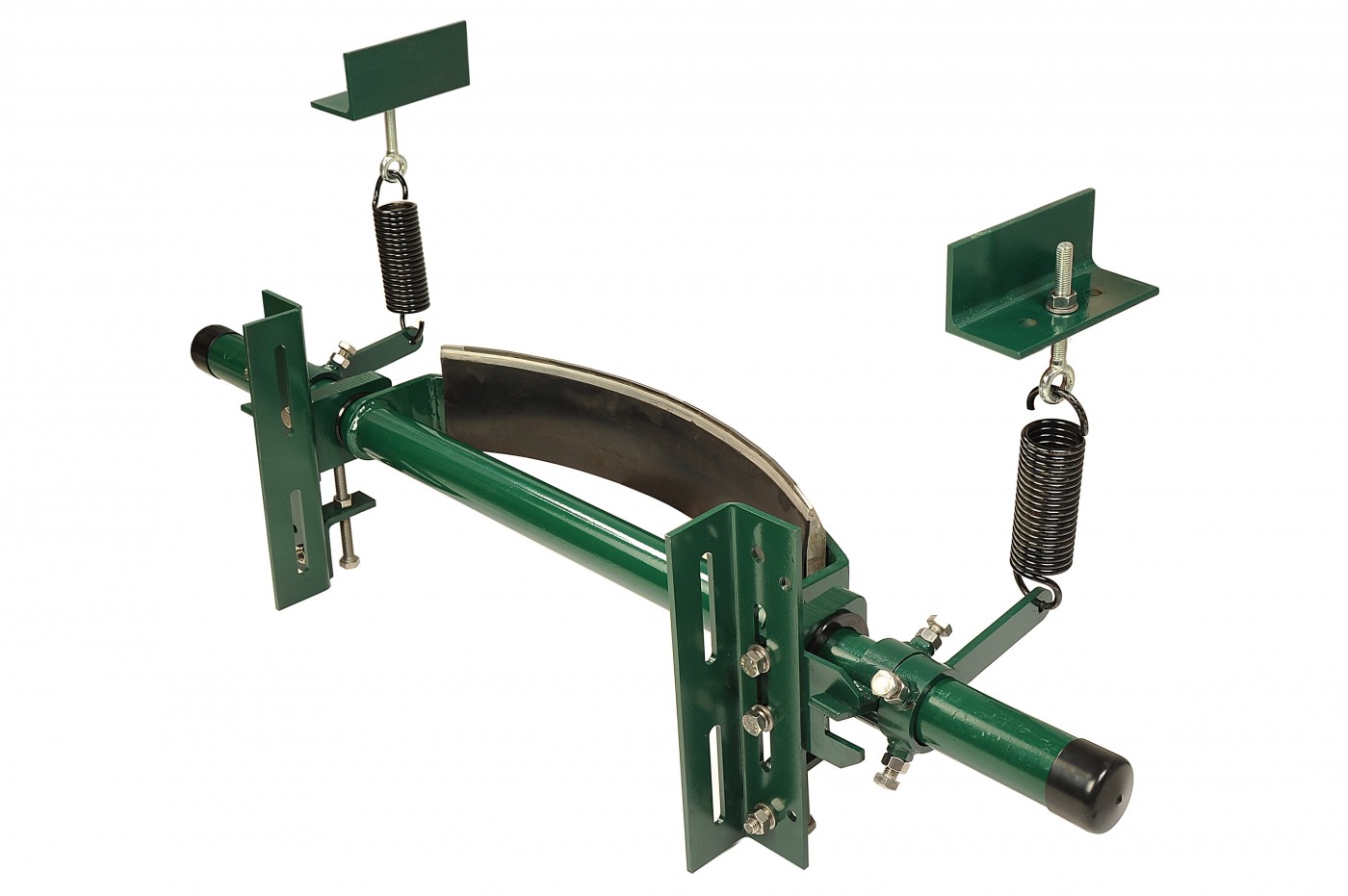

Curved Design for 100% Blade Contact

Because of this uneven wear, a gap can appear in the centre allowing carry back material through and thus compromising the effectiveness of the system.

The shape of the D-type cleaner addresses this problem by maintaining even wear across the entire belt width, ensuring superior performance throughout the life of the cleaner.

The outstanding performance exhibited by the D-type has secured its position as one of our most popular cleaning systems.

D-Type Belt Cleaner Features & Benefits

- Covers the whole belt for the whole of its life at an even pressure – this prevents blade wear, ensuring blades wear evenly, saving money

- Modular blade unit design for easy replacement – minimising downtime & maximising operational productivity

- The system is belt-friendly and damage-free operation is guaranteed – saving the cost of belts and dramatically increasing the life of conveyor belts

- Provides outstanding performance on sticky materials due its unique design and ability to apply maximum pressure in the centre of the belt – no clogging means no down-time

- Clog-free operation – keeping your plant running with little or no maintenance

- Robust construction makes the D-type suitable for heavy-duty high-speed conveying systems – it doesn’t matter how fast your belt is running or if you change the speed of your belt

- Range of widths from 450mm-2200mm – you can fit it on anything

- Optional spray bar can be fitted to help with semi-dry sticky products – reduced clean-up

- Self-adjusting capability with four options: Spring, Air bag, Torsion tube, Hydraulic

Upgrade your conveyor belt cleaning system with the cutting-edge technology of the PR-Type Conveyor Belt Cleaner. Designed for reliability and performance, this cleaner removes excess material and debris from conveyor belts, preventing spillage and reducing the risk of equipment damage.